An example of Digital Twins application for steel production

In the CAPRI steel use case the concept of Digital Twins (DT) is used to provide a product-centric view on the process data. It is based on a digital footprint of a physical object (so called digital shadow), in our use case of a steel long product. The DT is fed by a one-way data flow with the state of the object. A change in state of the object leads to a change in the digital object, but not vice versa. The DT therefore transfers a physical object into the virtual world, leading to a sufficiently accurate digital image of the object.

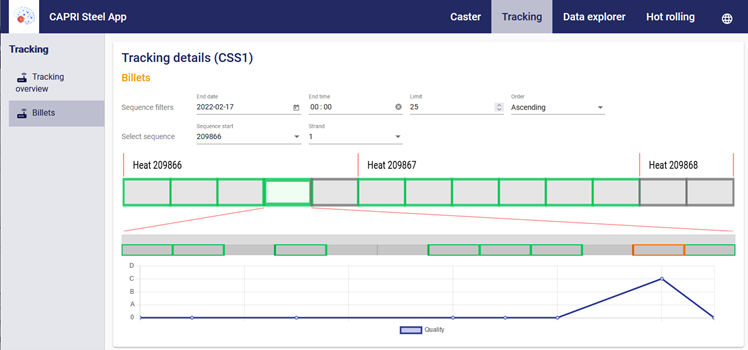

In the CAPRI project, a significant amount of production data has been collected and fed into the DT. This includes the steel composition, casting timeseries data, such as the casting speed and tundish temperature, billet tracking data, various datapoints from the hot rolling mill, such as temperature measurements, rolling forces, etc., and steel bar surface quality information.

Furthermore, the soft sensors CSS2 (steel solidification sensor for the continuous casting process), CSS3 (temperature soft sensor) and CSS4 (scale sensor) have been applied to the existing process data and enhanced it by means of derived data [1].

Since the sensor data from the automation system is usually time-related, a conversion or an interpretation of the data needs to be done by the twin, either upon ingestion or on the fly at retrieval time. The DT then offers an API for application development that is based on product ids instead of time as the main reference. Furthermore, the twin comes with a graphical user interface that allows for fine-grained insights into the state of the production items (products and machines).

All these collected data are now related to the product, for example on the length basis. The data are used in the CAPRI project to train data driven models like the anomaly detector (CSS5), which estimates the risk of producing an item with insufficient surface quality [2].

The DT provides an application programming interface (API) based on a domain-specific data model for applications such as soft sensors, data-driven analytics modules, or visualizations. The API enables the development of further capabilities of the twin, including reasoning and communication with external systems. This way, the twin can for instance listen in a data stream for the occurrence of an event, it can take autonomous decisions or provide recommendations to the user, and proactively speak to other DTs or other systems [3].

This type of DT has already been successfully used in applications such as agent-based trading, predictive maintenance or even anomaly detection.

References:

[1] https://www.capri-project.com/technology

[2] https://doi.org/10.5281/zenodo.6397468

[3] Neuer, Marcus J.: “On the concept of digital twins: technological background, communication and examples, including problems where no other effective solution exists - Introduction into DT”, ESTEP Workshop “Digital Twin technology in the steel industry: from concept to operational benefits”, 21.-22.11.2018, Charleroi (BE)